1、How to remove scratches?

Why the scratches are produced:

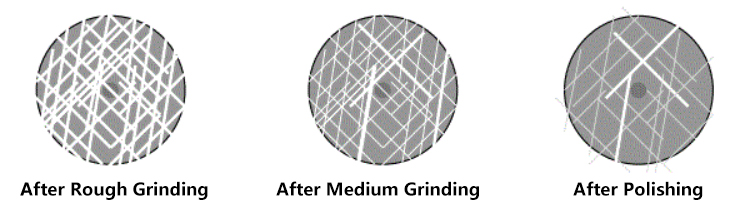

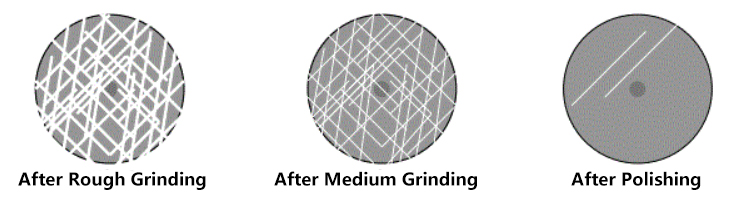

(1) The time of medium polishing is too short:every process is to reduce the roughness of the end-face. If the polishing time is not enough, some big scratches will remain on the end-face, and HF5D has no way to remove these big scratches.

Performance: Deep and light scratches remain on the end-face.

How do you remove these scratches?

Start regrinding from the medium grind. Increase the grinding time so that the end-faces are well ground.

(2)Residual abrasive debris on the polished front face: Fragments of abrasive sandpaper may also come off during rough and medium grinding. If these residues create friction on the end face during the grinding process, scratches can therefore occur.

Manifestation: One light scratch or a number of parallel light scratches.

How to remove scratches?

Start grinding again from the center grind. The grinding time depends on the depth (width) of the scratch.

- Slight small scratches: polishing time only 15s;

- Light minor scratches: the time for medium grinding is halved and the time for polishing remains the same;

- Deep scratches: same time for medium grinding and polishing.

2、How to reduce scratches?

(1) Increase the grinding time of medium grinding: In order to reduce the roughness and remove the deeper scratches, you can adjust the time of medium grinding to 30~60s.

(2) Clean the grinding end face: after each grinding, there will be residue left from grinding on the insert end face and fixture, which must be cleaned by wiping with dust-free paper dipped in distilled water or alcohol.

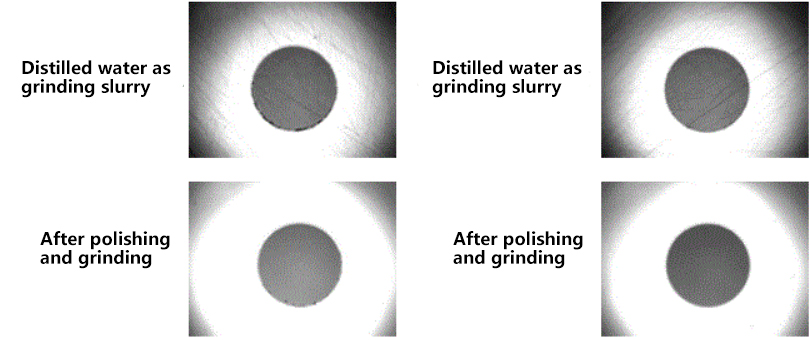

(3) Glue ring: Compared with zirconium and glass, the hardness of glue is much softer, which sometimes causes breakage of the glue ring during rough and medium grinding. The combination of distilled water and diamond powder abrasive sandpaper will produce big wear on the glue ring. PL-50 can effectively solve this problem, and can make the glue ring get slight grinding without causing serious breakage and erosion of the glue ring.