Fiber Optic Cleaner Usage Guide

I do not talk about fiber polishing today only about cleaning, we can not underestimate the role of end-face cleaning. In the fiber optic network before the operation of the fiber optic end-face inspection, in fact, a large part of the reason is also for better cleaning of the fiber optic end face. Ours today to inventory which you do not know the use of fiber optic cleaner, ready to accept the knowledge point oh!

Shenzhen Neofibo as a leading manufacturer of optical communication industry, not only focusing on the field of fiber optic polishing, in the optical communication network construction, maintenance and other aspects can also provide users with perfect solutions. Today is mainly about in the fiber optic end face cleaning small achievements. In order to better clean the optical fiber/end-face of different application scenarios, Neofibo has launched several cleaning products for different application scenarios, LC-125-C/SC-250-C/CLN-MPO-C fiber optic cleaning pen, US-500 fiber optic cleaning box, EDV-838 electric fiber optic cleaning pen.

LC-125-C/SC-250-C/CLN-MPO-C Fiber Optic Cleaning Pen:

LC-125-C/SC-250-C/CLN-MPO-C three fiber optic cleaning pen are pressed fiber optic connector cleaning supplies, cleaning life of more than 600 times, are effective in removing a variety of oil and dust, in order to avoid contamination of the cleaning pen are with a dust cap. The difference between these three cleaning pens lies in the different connector interfaces applied: LC-125-C for 1.25mm LC/MU (APC&UPC) fiber optic interface, SC-25-C for 2.5mm SC/ST/FC/E2000 (APC&UPC) fiber optic interface; CLN-MPO-C for MPO/MT (APC&UPC) fiber optic interface. UPC) for fiber optic interfaces.

Usage:

Fiber optic cleaning pen lightly inserted into the fiber optic interface to be tested, can not be too hard to damage the core, inserted after gently pressed inward, when you hear a “Ka Ka” sound, that the end face cleaning has been completed, if you are worried about a cleaning is not in place, you can repeat the operation of the press more than 2 to 3 times, and then pull out the cleaning pen, this is the entire cleaning process.

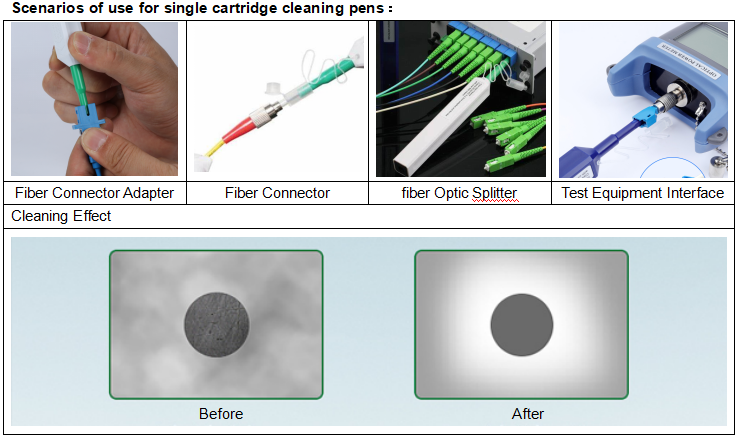

Scenarios of use for single cartridge cleaning pens:

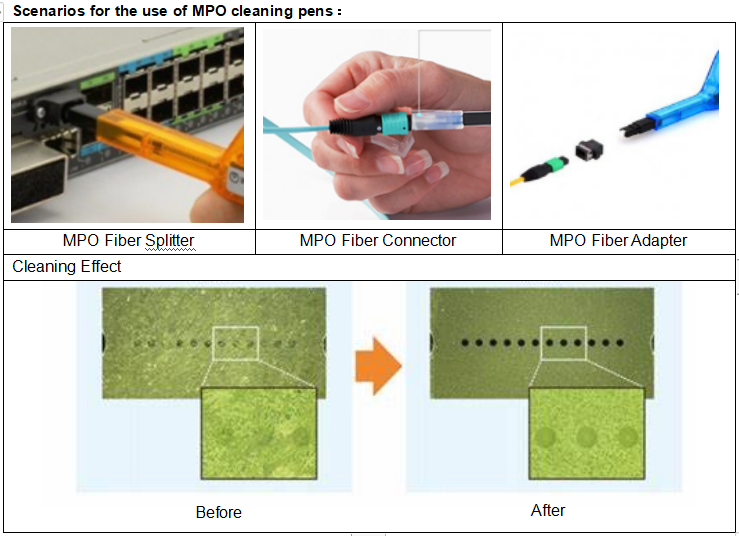

Scenarios for the use of MPO cleaning pens:

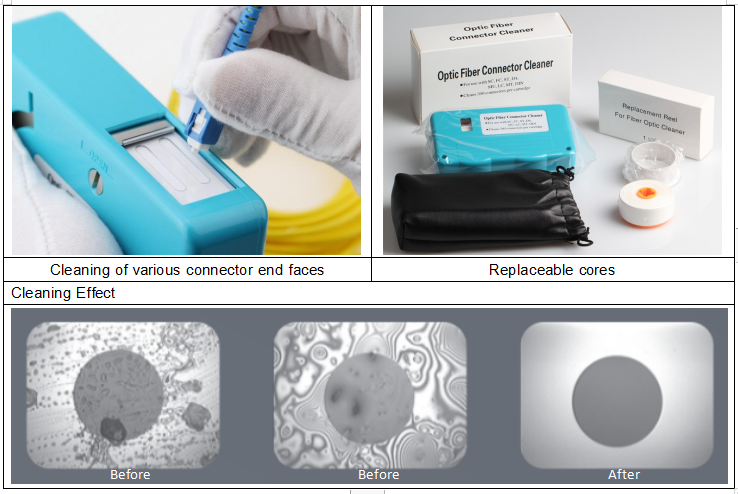

US-500 fiber optic connector cleaning box

US-500 fiber optic connector cleaning box adopts non-alcohol special microfiber, cleaning effect is fast and effective, cleaning times up to 500 times; cleaning tape is made of high-density textile fibers, suitable for FC/SC/LC/ST/MU/D4/DIN and other fiber optic connector ferrule end face cleaning, can be replaced by the core of the tape; the design of the lightweight, portable, drop-proof, can be applied to different environments.

Usage:

When using, hold the cleaning box with one hand, by pressing the cleaning box switch to expose the clean cleaning tape core, and then the fiber optic insert to be tested on the cleaning tape gently wiped a few times, do not use too much force so as not to damage the insert, so that the dirt attached to the end face will be removed cleanly.

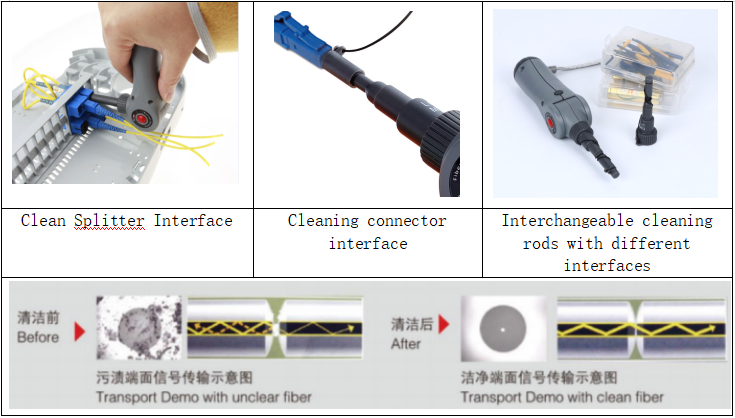

EDV-838 Electric Fiber Optic Cleaning Pen

The EDV-838 Electric Fiber Optic Cleaner dry cleans all dirt and contaminants from fiber optic connectors, ferrules and bulkheads. It attracts and removes dirt by motorized sweeping and cleans in seconds.

The unique cleaning rod inside the cleaner achieves 98% cleanliness in a wider space from the core to the ferrule and contact area. High temperature resistant material ensures that it will not break during use. Different types of connector cleaning stickers that rotate at different angles on the cleaner make it very easy to clean the hard-to-reach confined spaces of various connectors, including MPOs.

EDV-838 Electronic Fiber Optic Cleaner achieves cost effective cleaning of fiber optic patch cords, transceivers, patch panels, and equipment cleaning without secondary contamination.

All of the above are Neofibo’s own cleaning products, let’s take a look at the results of the use of other cleaning products, follow me down.

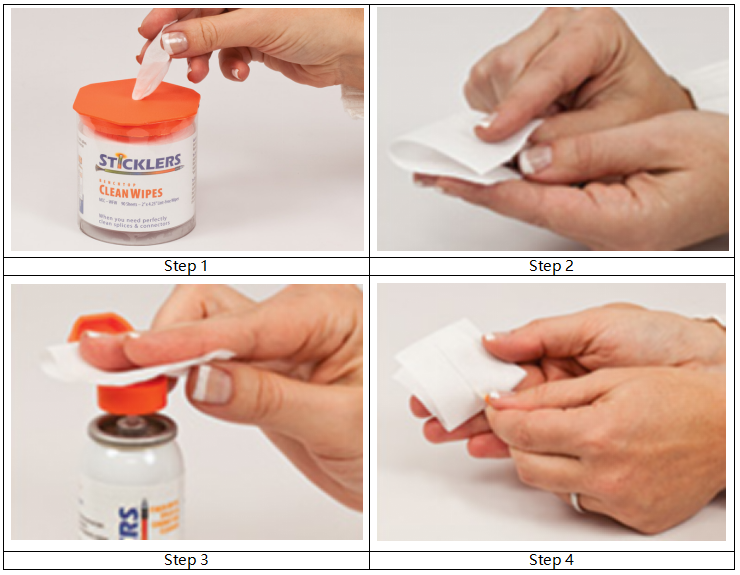

Kit 1: Wiping paper with cleaner to clean patch cord end faces or fiber without splices:

This task requires the MCC-POC03M Fiber Optic Cleaner and the MCC-WFW100 Lint Free Wiping Paper.

Clean the patch cord end-face:

Cleaning Fiber:

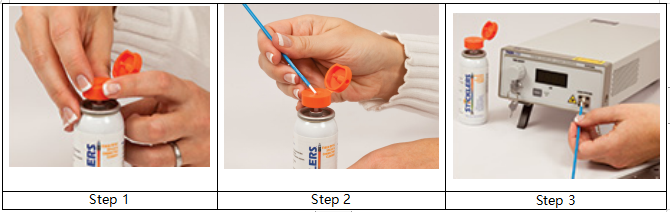

Kit 2: Cleaning Wand with Cleaner for Fiber Optic Sockets

This task requires the MCC-POC03M fiber optic connector cleaner and the MCC25 connector cleaning wand.

The above is a small inventory of all the use of fiber optic cleaner then, if you have any suggestions or comments, please contact me directly for your answer!