Visual Laser Cutting Machine,UVL-CM-10W

Model: UVL-CM-10W

Origin: China

Brand: Neofibo

Production Description:

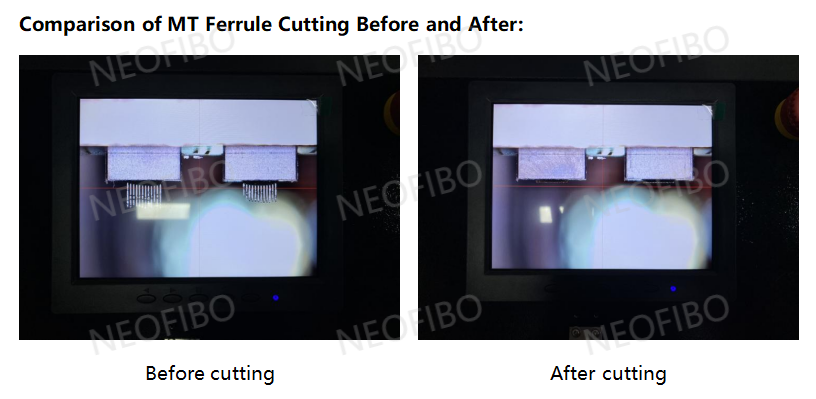

The UVL-CM-10W visual laser cutting machine is a device designed for the optical communications field to laser-cut and remove glue ferrules and excess fiber from single-core and multi-core fiber optic connectors/ferrules, focusing on products like single-core, MT, and FA connectors. It precisely removes glue ferrules and fiber tip, minimizing fiber notches and crescent defects while reducing fiber damage. This streamlines polishing processes and reduces polishing volume, saving time and improving test yield rates. Featuring high precision and ease of operation, it delivers smooth, burr-free fiber end-faces post-cutting—ready for direct polishing with enhanced results. This boosts efficiency significantly.

Key Features:

- Non-contact removal of glue ferrules/cutting of optical fibers, with no damage to fibers or ferrules;

- Frequency and power adjustable online, supporting single-pass/reverse-pass cutting, with single-pass cutting taking 1-3 seconds per fiber;

- Laser cutting of optical fibers/glue ferrule removal reduces polishing volume and prevents fiber nicks;

- Recommended post-cut fiber length extension: 200μm – 250μm;

- Quick-change ferrule fixtures compatible with single-core and multi-core (SC/LC/FC/MT/FA, etc.) cutting;

- Parallel ferrule surface cutting for fast, smooth cuts, reducing polishing steps;

- Visual operation system with adjustable X&Y-axis fixture positioning for precise length control;

- End-face to cut distance of only 0.05-0.08mm (<0.1mm) ensures high product consistency;

- Superior polishing finish on thick-cut ferrules with high 3D pass rate;

- Simple operation with safe scrap collection.

Applicable scenarios:

- Optical fiber manufacturing: In the mass production of optical fiber products such as bare fibers, MT/ceramic ferrules, and REC assemblies—including post-curing fiber insertion and cutting—it precisely removes fiber tip and glue ferrule, reducing defect rates and enhancing subsequent polishing efficiency.

- Optical Module Packaging and Testing: For pre-processing fiber assemblies within optical modules/devices, ensuring flat-cut end-faces for high-quality polishing and boosting test yield rates.

- Medical Fiber Component Processing: Achieving precise removal of glue ferrule in high-precision medical fiber device production, guaranteeing low fiber damage and smooth end-face finish to meet medical-grade quality standards.

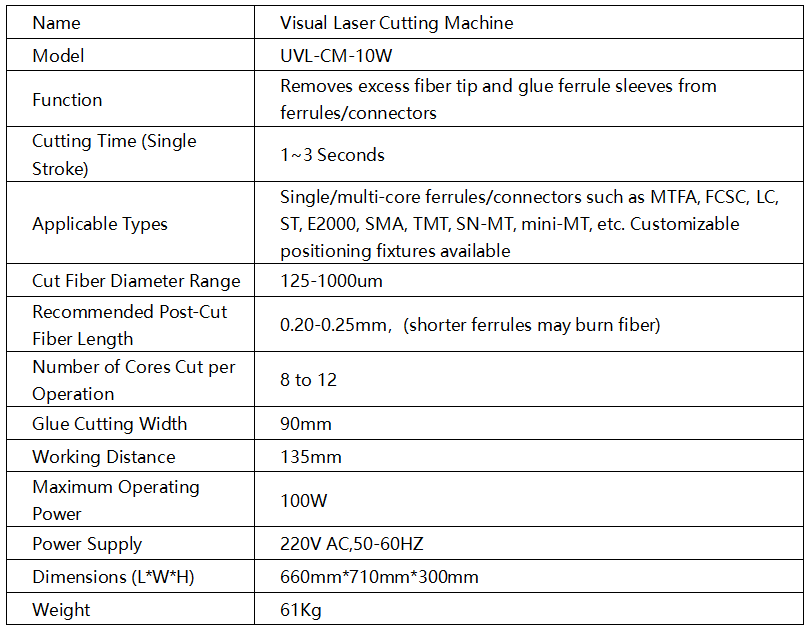

Equipment Parameters:

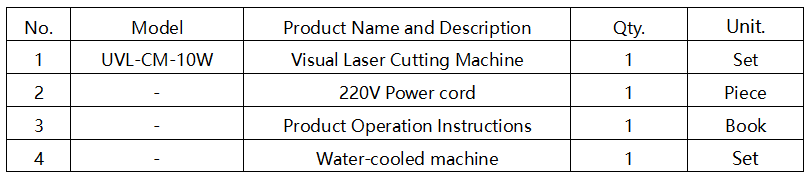

Configuration List:

Notes:

- Regularly clean the laser head lenses and optical path with specialized tools. Do not use ordinary cloths or chemicals for wiping.

- Periodically inspect the cooling system’s fluid level and heat dissipation to prevent laser module overheating, which may affect equipment lifespan and cutting stability.

- Promptly remove debris from the cut end-faces of products after processing. Randomly inspect end-face flatness; only proceed to subsequent steps if end-face are free of burrs and damage.

- Do not stack uncleaned products directly to prevent end-face collisions and contamination.

- Operators must be certified through training and assessment prior to work. They shall be familiar with emergency stop procedures and must immediately press the emergency stop button and report in case of equipment abnormality.

- Do not leave post while the equipment is running. Monitor the processing status in real time and promptly address issues such as material misalignment or parameter abnormalities.

- In case of malfunction, contact us immediately. Do not open the equipment housing on your own. Unauthorized opening will void the warranty.